We design everything that moves; for as long as we live, we move

We know the value of breaking outside the box and thinking differently, with a strong foundation and understanding of the market and users. BAMS combines years of design expertise in intelligent mobility with fluid engineering simulations to help you create your ideal products. No matter your product's stage, whether you seek technological breakthroughs or market innovation, our team transforms your concepts into tangible products aligned with your strategy.

We streamline development through integrated industrial design and engineering validation, enhancing both appearance and performance. With several optimisation and simulation analyses, we add unique brand value to your products.

BESPOKE

Research, Design & Engineering

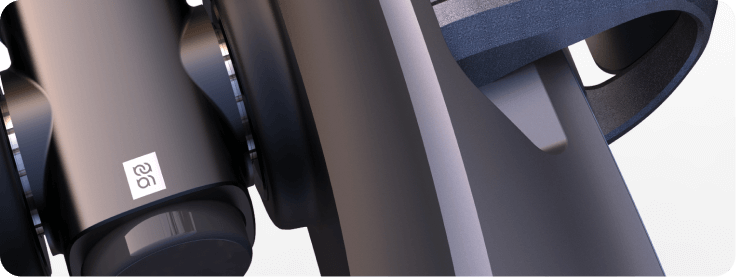

OVERHEAD HOIST TRANSFER

INDOOR ENVIRONMENT INSPECTION DRONE

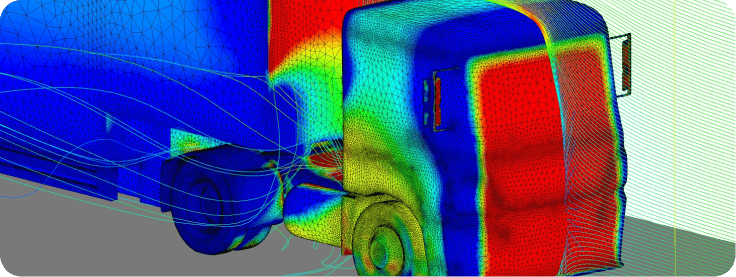

ENERGY EFFICIENT VEHICLE OPTIMISATION

FOUP STOKER

eVTOL Inlet Simulation

EV Research

Automated Vehicle Solutions, Overhead Transportation for Warehouse Operations

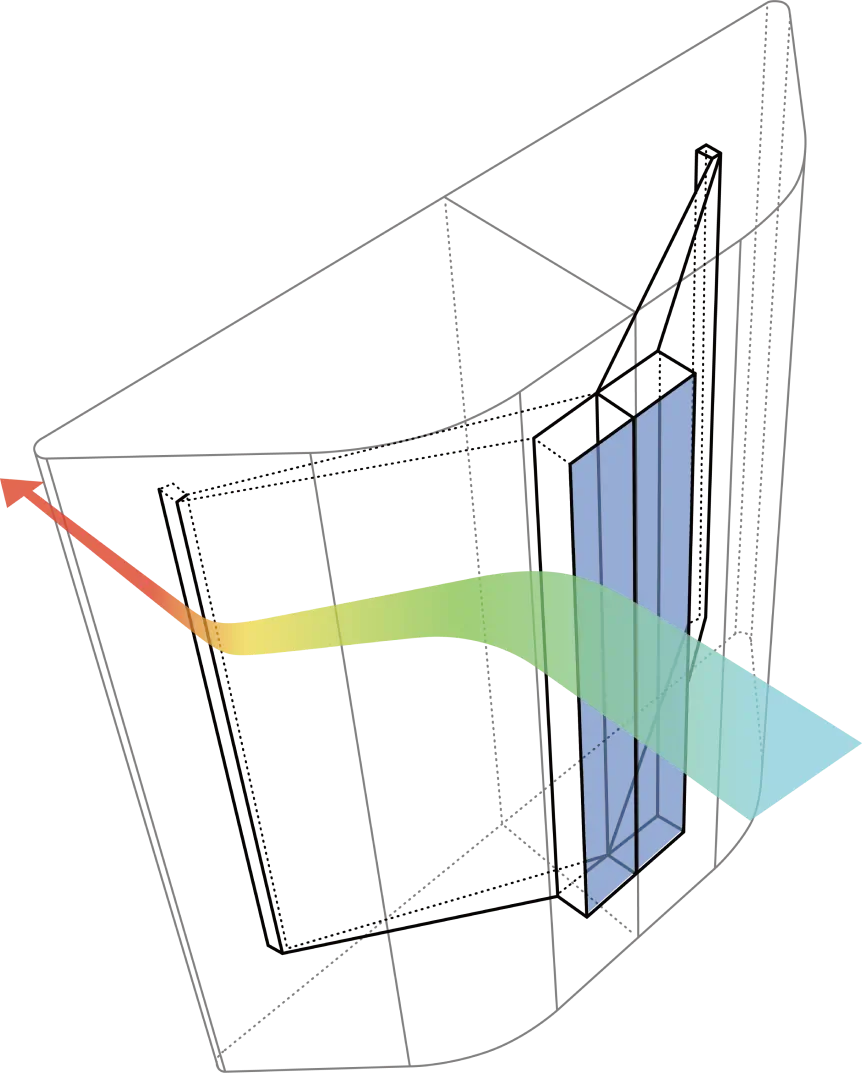

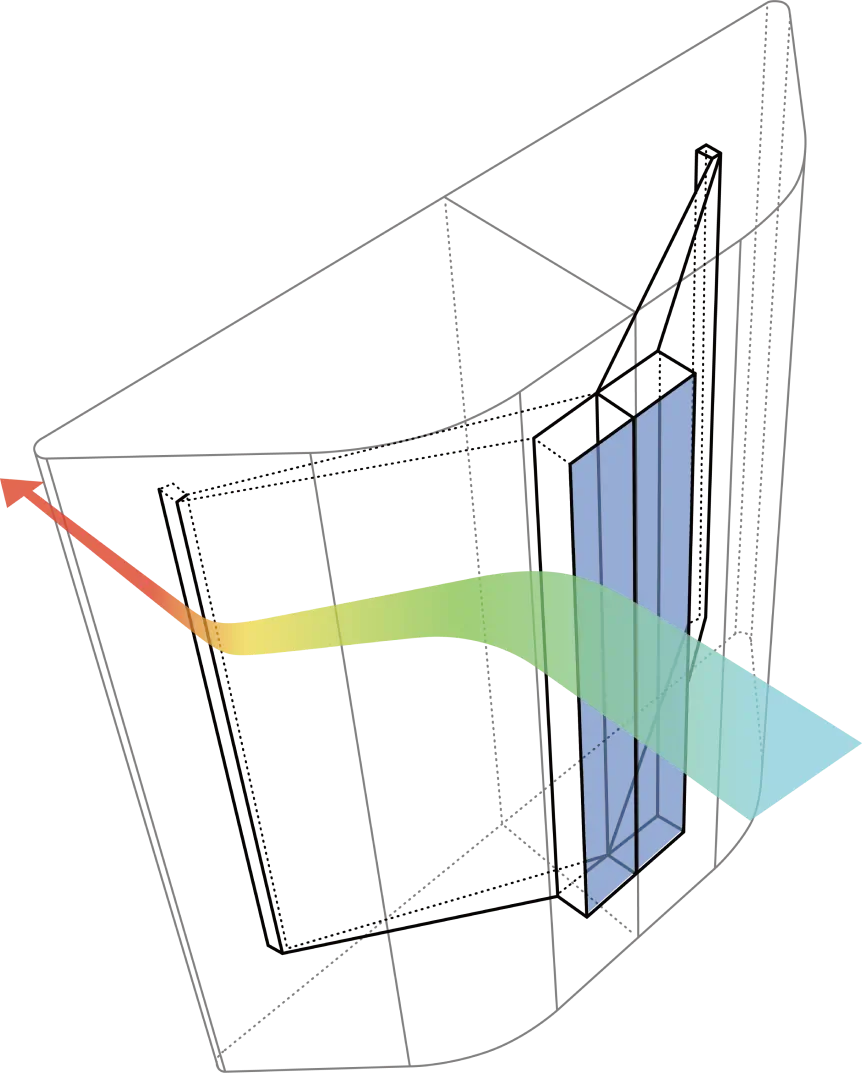

In the semiconductor industry, automated equipment is often used for the transportation of semiconductor wafers. However, during production and processing, problems such as machine or equipment operation may lead to the intrusion of outside air, resulting in an increase in dust particles which affects the quality and yield of wafers.

Unlocking Efficiency Improvements Through Aerodynamic Validation in New Territory

Traditional solutions in this space often include adding a door to reduce dust, which can lead to defects in semiconductor components. However, this approach also raises manufacturing costs and complexity. We achieved similar results without the need for added complexity.

Utilising experience and knowhow from the automotive industry we were able to reduce turbulent airflow as-well as accelerating and ducting the flow to create a virtual shield, which protected the components, increased efficiency and reduce the dust residue by 12.2%, without any moving parts

%

Reduced Dust Residue

Moving Parts

%

Reduced Dust Residue

Moving Parts

Connected Systems and Compounded Problems

This Overhead Hoist Transfer System operates at the beginning of a wider manufacturing process. As a result any dust or debris picked up at this stage follows the product down the production line, introducing defects and increasing subsequent waste product.

Understanding and solving these challenges are key to optimising a businesses yield and profitability. Some studies have shown that being able to increase yield by just 0.1% profitability can be increased by $100m

Yield Difference

Profitabilty Difference

Discover, Optimise, Sustain

Discover how you can optimise your offering, Optimise your efficiency for a more Sustainable future.